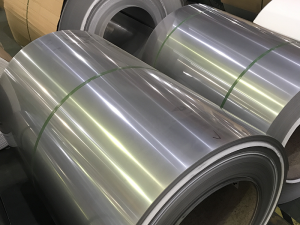

410S Coil ea tšepe e sa hloekang

Tlhaloso

Litlhaloso:

1.E tloaelehileng: ASTM A240, JIS G4304, EN10088

2. Sehlopha: 200series&300series&400series

3. Botenya: 0.03mm - 6.0mm

4. Bophara: 8mm-600mm

5. Bolelele: joalo ka kopo ea bareki

6. Surface: 2D,2B, BA, Mirror e felile, N04, Hair Line, Matt finish, 6K, 8K

7.Theknoloji: ho huloa ka serame / ho bata ho pota / ho chesa ho kolobisitsoe

Lisebelisoa:

| Mofuta | Kereiti | Kereiti | Karolo ea Lik'hemik'hale % | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Tse ding | |||

| Austenitic | 201 | SUS201 | ≤0.15 | 16.00-18.00 | 3.50-5,50 | 5.50-7.50 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 | - |

| 202 | SUS202 | ≤0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ≤0.060 | ≤0.030 | ≤1.00 | - | ≤0.25 | - | ||

| 301 | 1.4310 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | ≤0.10 | - | |

| 304 | 1.4301 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304L | 1.4307 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304H | 1.4948 | 0.04-0.10 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309 | 1.4828 | ≤0.20 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309S | * | ≤0.08 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 310 | 1.4842 | ≤0.25 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 310S | * | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 314 | 1.4841 | ≤0.25 | 23.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | 1.50-3.00 | - | - | - | |

| 316 | 1.4401 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316L | 1.4404 | ≤0.030 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316Ti | 1.4571 | ≤0.08 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | 0.1 | Ti5(C+N)~0.70 | |

| 317 | * | ≤0.08 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 317L | 1.4438 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 321 | 1.4541 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 321H | * | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 347 | 1.4550 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C% -1.10 | |

| 347H | 1.494 | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C% -1.10 | |

| Duplex | 2205 | S32205 | ≤0.03 | 22.0-23.0 | 4.5-6.5 | ≤2.00 | ≤0.030 | ≤0.020 | 3.0-3.5 | ≤1.00 | - | 0.14-0.20 | |

| 2507 | S32750 | ≤0.03 | 24.0-26.0 | 6.0-8.0 | ≤1.20 | ≤0.035 | ≤0.020 | 3.0-5.0 | ≤0.80 | 0.5 | 0.24-0.32 | ||

| Ferrite | 409 | S40900 | ≤0.03 | 10.50-11.70 | 0.5 | ≤1.00 | ≤0.040 | ≤0.020 | - | ≤1.00 | - | ≤0.030 | Ti6(C+N)~0.50 Nb:0.17 |

| 430 | 1Kr17 | ≤0.12 | 16.00-18.00 | - | ≤1.0 | ≤0.040 | ≤0.030 | - | ≤1.0 | - | - | - | |

| 444 | S44400 | ≤0.025 | 17.50-19.50 | 1 | ≤1.00 | ≤0.040 | ≤0.030 | 1.75-2,5 | ≤1.00 | - | 0.035 | Ti+Nb:0.2+4(C+N)~0.80 | |

| Martensite | 410 | 1Kr13 | 0.08-0.15 | 11.50-13.50 | 0.75 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 410S | * | ≤0.080 | 11.50-13.50 | 0.6 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420 | 2Kr13 | ≥0.15 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420J2 | 3Cr13 | 0.26-0,35 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| PH | 630 | 17-4PH | ≤0.07 | 15.00-17.50 | 3.00-5.00 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | 3.00-5.00 | - | Nb 0.15-0.45 |

| 631 | 17-7PH | ≤0.09 | 16.00-18.00 | 6.50-7.50 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | ≤0.50 | - | Al 0.75-1.50 | |

| 632 | 15-5PH | ≤0.09 | 14.00-16.00 | 3.50-5,50 | ≤1.00 | ≤0.040 | ≤0.030 | 2.00-3.00 | ≤1.00 | 2.5-4.5 | - | Al 0.75-1.50 | |

Lintlha tsa motheo

410s Stainless Steel Coil, e nang le khanyetso e ntle ea kutu le machinability, ke tšepe ea morero o akaretsang le tšepe ea sesebelisoa sa ho seha.410S ke mofuta oa tšepe o ka ntlafatsang ho hanyetsa ha kutu le sebopeho sa tšepe ea 410. 410S ke tšepe e matla e phahameng e ka ntlafatsang ho hanyetsa ha kutu ea 410 tšepe.E sebelisoa bakeng sa likhaba tsa turbine le likarolo tse phahameng tsa mocheso.

• Litlhaloso: AISI 410s, ASTM 410s

• E qeta: Ba holim'a metsi, 2b holim'a metsi, No.1 (letlalo le lesoeu), 2D holim'a metsi, No.4 (frosted), HL (terata), 8K e na le boleng bo botle ba holim'a metsi.

•Mill tolerances ka botenya & flatness e sebetsa.Bitsa JM Steel haeba o hloka boholo bo itseng kapa tataiso ea lijo-thollo.

Theknoloji ea machining ea 410S

1D -- Bokaholimo bo na le sebopeho sa granular, se tsejoang hape ka hore ke moholi.

Theknoloji ea ho sebetsa: ho bilika ho chesang + ho phunya ho phunya + ho kolobisa ho batang + ho hlatsa

2D - Mmala o mosoeu hanyenyane.

Theknoloji ea ho sebetsa: ho bilika ho chesang + ho phunya ho phunya + ho kolobisa ho batang + ho hlatsa

2B -- Bosoeu ba silevera bo benyang bo betere le bo bataletseng ho feta bokaholimo ba 2D.

Theknoloji ea ho lokisa: ho bilika ho chesang + ho phunya ho phunya + ho kokota ho batang + ho kokota + ho kokobela + ho tima le ho kokobela.

Ba - Gloss e ntle ka ho fetesisa, e bonts'ang haholo joalo ka seipone.

Theknoloji ea ho lokisa: ho bilika ho chesang + ho phunya ho phunya + ho kolobisa ho batang + ho hlatsa + ho penta ka holim'a metsi + ho tima le ho kokobela.

No.3 -- Gloss e ntle, bokaholimo ba lijo-thollo tse mahoashe.

Theknoloji ea ho sebetsa: ho bentsa le ho futhumatsa bakeng sa 2D kapa 2B ka lisebelisoa tsa abrasive tse 100 ~ 120 (JIS R6002).

No.4 -- Gloss e ntle, mela e metle ka holimo.

Ts'ebetso ea ho sebetsa: ho bentsa le ho futhumatsa bakeng sa 2D kapa 2B ka lisebelisoa tsa abrasive tse 150 ~ 180 (JIS R6002).

HL -- Silver grey e nang le methalo ya moriri.

Theknoloji ea ho sebetsa: Lihlahisoa tsa 2D kapa lihlahisoa tsa 2B tse nang le granularity e loketseng ea lisebelisoa tsa abrasive bakeng sa ho bentša bokaholimo ke lijo-thollo tse tsoelang pele.

MIRRO -- E ikhethang.

Theknoloji ea ho sebetsa: Lihlahisoa tsa 2D kapa lihlahisoa tsa 2B tse nang le granularity e nepahetseng ea thepa e silang le ho bentša ho phello ea seipone.